So, I made a pair of huge asymmetrical earrings:

Clearly they go well with bright red lipstick.

Okay, so I’m not going to go into the whole blow-by-blow of how to make something using lost-wax casting again. If you want to read about that, go here.

I did, however, chronicle making these earrings, so I’m just going to picture dump BECAUSE I CAN!

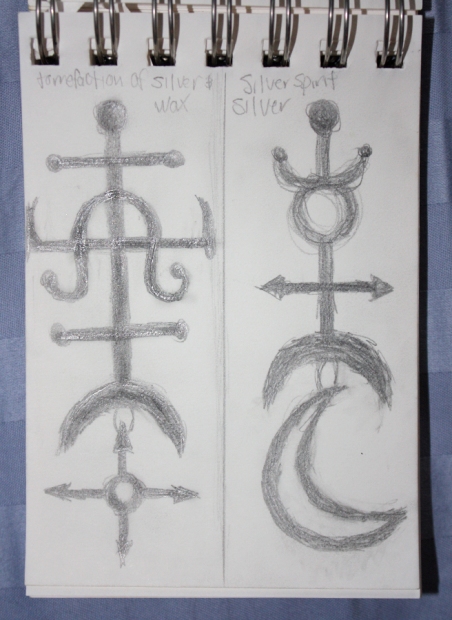

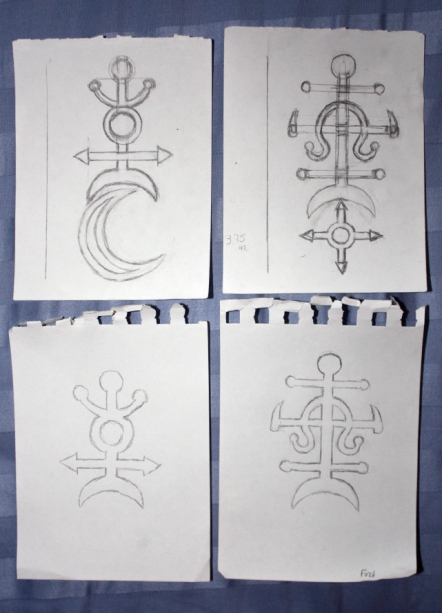

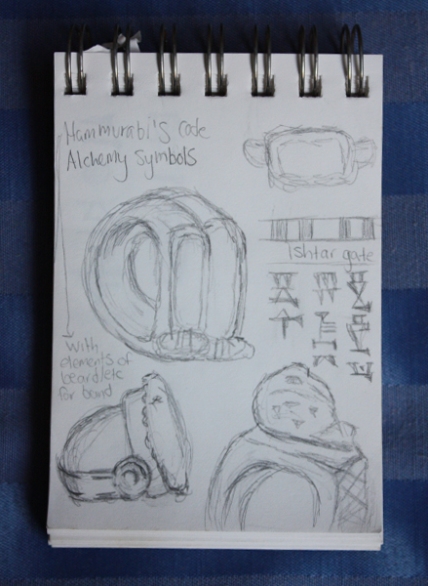

DESIGN PHASE

I had the idea to make something with alchemy symbols for a while. I was going to somehow do a ring of it, but it was impractical. So here is the fruition of my alchemy idea! I first chose my symbols based on meaning and design appeal. I didn’t want them to be just random symbols with no connection to anything, so I chose the symbols for silver, silver spirit, the torrefaction of silver, and wax. I’m So Meta Even This Acroynm (thank you, XKCD). I had to redesign the alchemy symbol for silver spirit just slightly as you can see by adding a top part for the post/symmetrical reasons. I also added arrows to it so that it would better connect to the other earring and not look totally unrelated.

Straight lines are not my friends. I am terrible at drawing straight lines, as evidenced above. I was also super careful to make sure that the earrings were of the same length. Asymmetrical is one thing, but different lengths is annoying (at least to me).

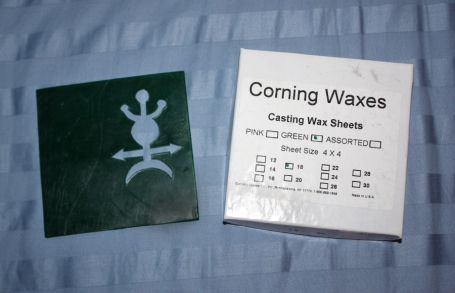

WAX PHASE

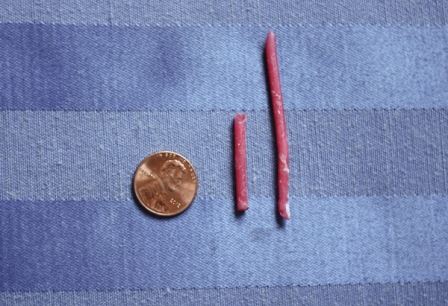

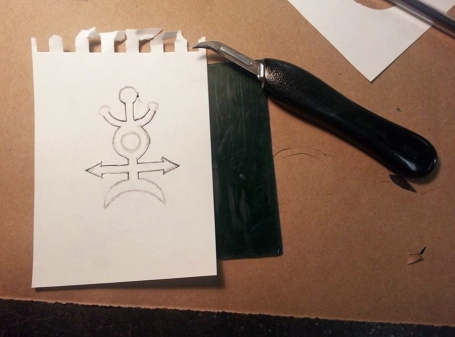

I used wax sheets (seen above). Using the master drawings of the earrings, I traced copies and then laid the drawing over the wax sheet. I used a knife to cut the outline of the symbol in wax.

Taken with my phone, hence the weird color.

This was a good deal more difficult than it sounds. I initially tried to use an x-acto knife, but the shape of the blade resulted in strange pressure issues on the sheet of wax and instead of cutting cleanly, it more or less tore it. The curved blade (above) was perfect (although in a moment of idiocy, I cut my thumb open with it…).

Here we see a bunch of paper cut-outs and a reject silver spirit made of wax. Oddly, it was the less-complicated silver spirit symbol that gave me the most trouble.

CASTING IN METAL PHASE

By some miracle, I managed to cast all the pieces together in one cylinder. As you can see in this picture, I ran out of time (as usual) and didn’t fully clean off the investment from casting. I also hadn’t dipped it in the acid, so that’s why it’s not white. I made the holes for the jump rings (the ring that holds the two pieces together) in wax using the tip of a jewelry blade because it was much easier than drilling into metal.

FINISHING PHASE

Here are the pieces detached from the sprues, dipped in acid, but before being filed down.

Here are the sprues. I used a pair of shears to cut some of them off because, as mentioned in another post, it’s less accurate but much faster. I did use a saw for a few of the sprues, though, because they were attached the back of the piece and filing down the nubs left over from the shears would have taken me forevvveeerr.

So after filing down the pieces (which took a while), I polished them up using a polishing machine. Let me just say, you need to have a very firm grasp on your piece while polishing it or it will fly out of your hands. That obviously happened to me…and those moon points and arrows are sharp. Needless to say, I gave myself a few stab marks trying to polish the pieces.

Finding jump rings that fit the small holes I made was a bit tricky but after some trial and error at AC Moore and Michaels, I managed to find some that fit (it also involved using a jewelry saw blade to widen the holes slightly). And in my most controversial decision– it made every jewelry-maker I talked to make a very judgy, disgusted face– I glued (yes, glued) the posts to the back of the earrings. (Shhh, don’t tell.) I basically ran out of time and soldering is not my strong point. In my defense, the posts are holding very well.

And finally, in what was the most distasteful part of the process, I slapped on bright red lipstick and took about 500 selfies of myself wearing the earrings. Taking close ups of my face/skin is definitely not on my Favorite Things list (it’s just after talking about feelings and eating glass), but I don’t have a model available.

BONUS PICTURES:

THEY ARE SO SHINY. No really, they are super shiny and catch the light when you move your head. And I adore them.

I felt like the shininess didn’t show as well in the picture with a black background.

Mugshot wearing them to prove I have a top-half of a face.

All in all, I really, really, really like them a lot and will actually probably wear them in public. Which is progress, considering I almost never wear anything I make. They are huge and shiny, and that is all I want in anything (but especially earrings).